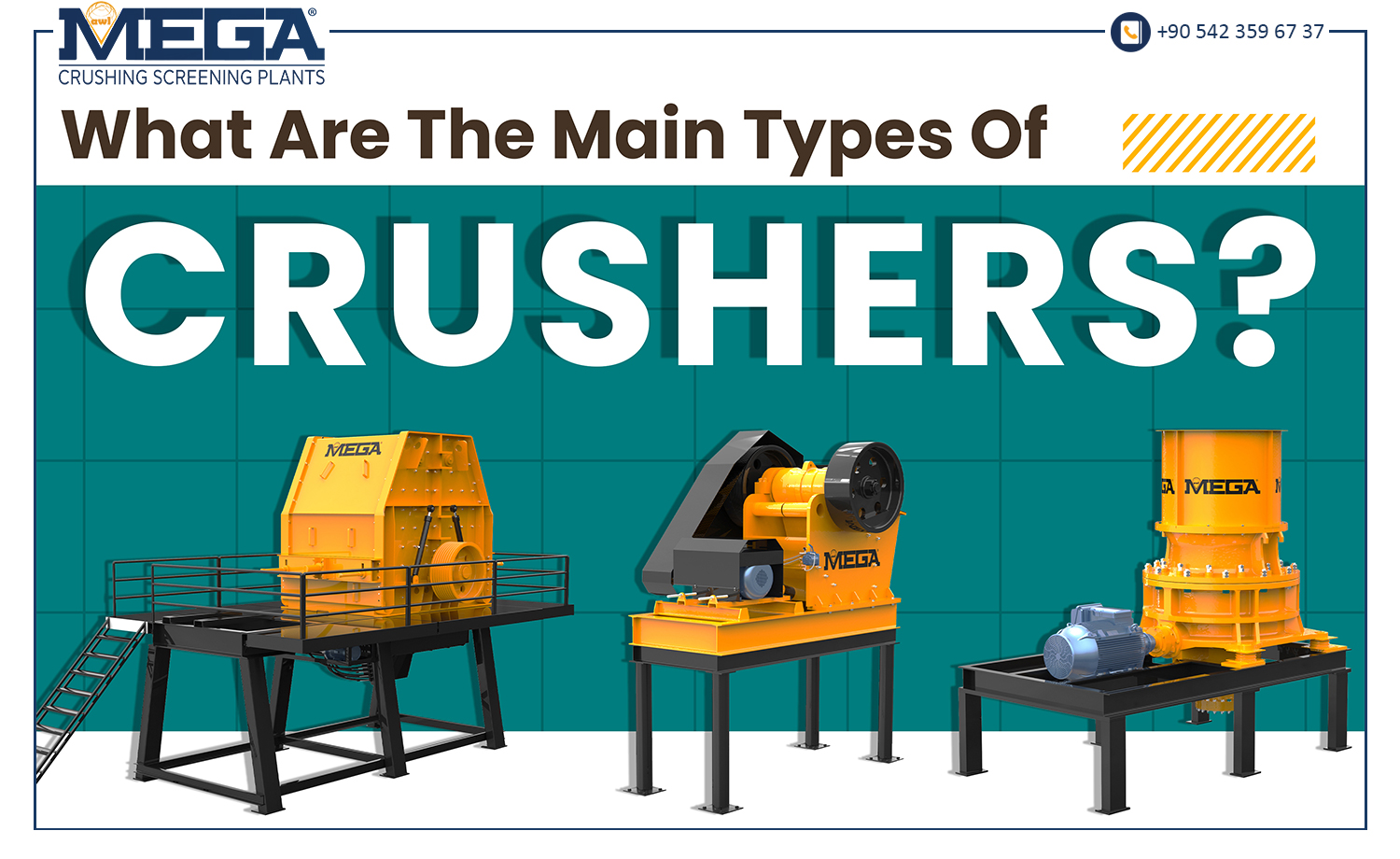

What Are The Main Types Of Crushers?

MAIN TYPES OF CRUSHERS INTRODUCTION In the world of industrial equipment, crushers are a crucial part of crushing and screening

We provide 24/7 service with our entire team to offer the highest quality products and solutions to our customers in 5 continents and 52 different countries.

We prove that we “Advancing quality further with 25 years of industry experience” by giving a 2-year warranty for our stone crushing,screening – washing plants, which can be easily assembled thanks to the designs of our engineers suitable for every project and can be easily dismantled and moved to another area in a short time when desired. We are the leading stone crushing, screening manufacturing company with years of experience, quality understanding, R&D activities, and a perspective that constantly renews itself.

As Mega Stone Crushing Screening Plants manufacturing company, you can get in touch with us to review videos from our completed projects provided by our customers and to acquire more detailed information about our company.

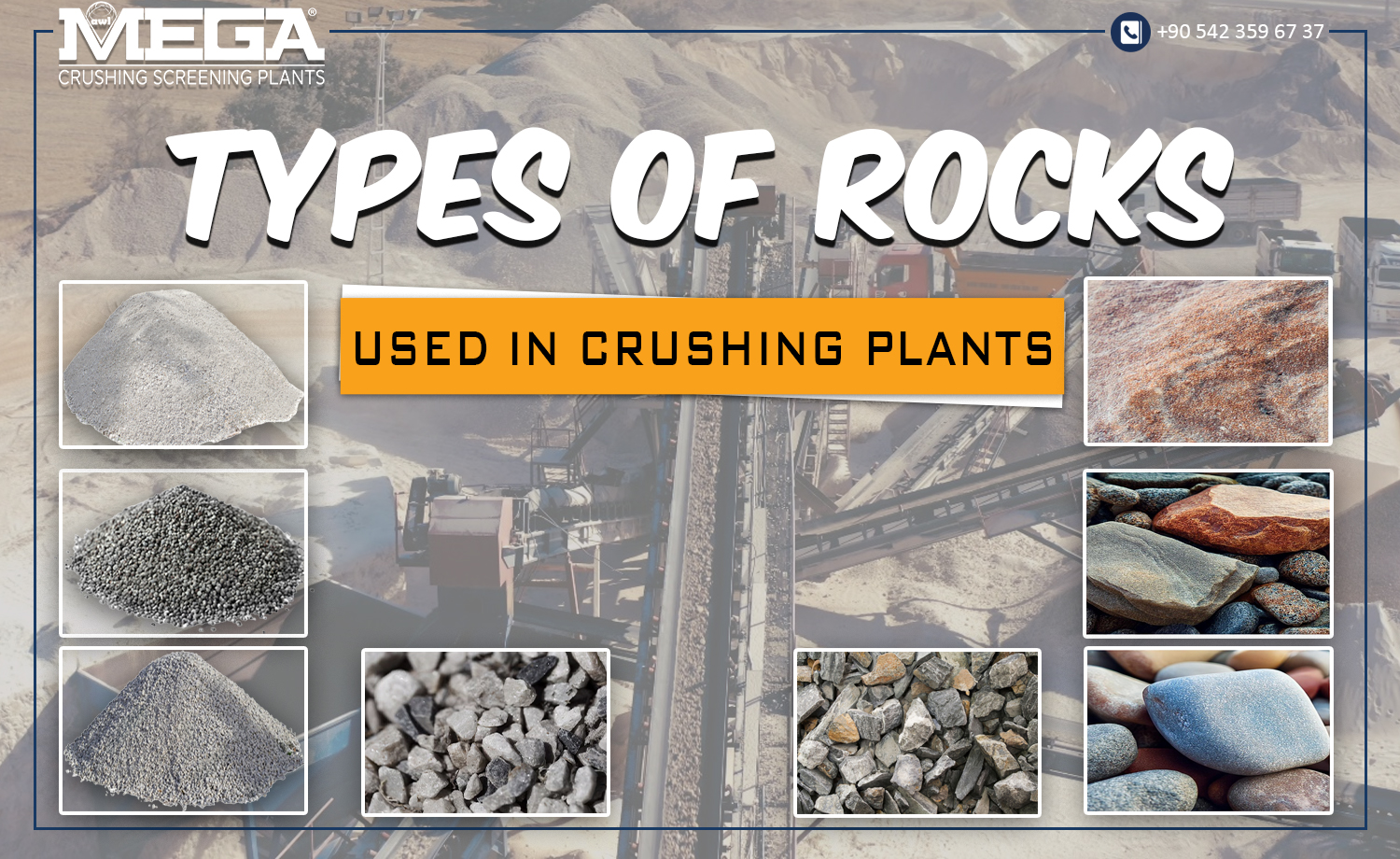

Designed for crushing hard and abrasive materials such as Basalt, Gabbro, Granite and Creek Materials, it has an important role in reducing operating costs, especially thanks to its low abrasion rates.

They are the latest crushers capable of crushing all kinds of stones. Since their feed sizes are not very large, they cannot be used as secondary crushers. The products obtained from Vertical Shaft Impact Crushers are cubic in shape, and they have high fineness ratios. Therefore, they are extremely advantageous crushers, especially in the production of ready-mix concrete and asphalt materials

Hammer crushers operate on the principle of crushing materials through high-speed rotating hammers or rotors. These crushers are used especially for breaking down hard and durable materials.

Vibrating Screens can be produced horizontally and inclined. While Horizontal Screens Work Linearly, Inclined Screens Move Circularly with an Angle of Approximately 20 Degrees. Thanks to their vibration systems, vibrating screens have the ability to operate at high speeds. Vibration Capacities are Designed to be Adjustable. Screens with Steel Main Body are Produced Suitable for Long Years of Usage.

Jaw Crushers perform the crushing process by compressing materials between movable and fixed jaw plates. These crushers are effective in breaking hard and medium-hard materials.

Tertiary crushers are used for the crushing of soft and medium-hard materials. Tertiary crushers perform much finer crushing compared to secondary impact crushers. Therefore, they can be used as the third and final crusher.

Screeners are important equipment that must be present in Crushing, Screening, and Washing Plants. After the crushing process, they enable the separation of particles based on their sizes. They consist of spiral springs. The smallest particles pass through quickly, while larger particles are moved more slowly to carry out the screening process.

* The Crusher Plant With A Diameter Of 90 Cm Has A Production Capacity Ranging From 125 Tons Per Hour To 180 Tons Per Hour

* The Crusher Plant With A Diameter Of 110 Cm Has A Production Capacity Ranging From 250 Tons Per Hour To 350 Tons Per Hour

* The Crusher Plant With A Diameter Of 125 Cm Has A Production Capacity Ranging From 350 Tons Per Hour To 450 Tons Per Hour

* The Crusher Plant With A Diameter Of 140 Cm Has A Production Capacity Ranging From 450 Tons Per Hour To 600 Tons Per Hour

If you want to have a crushing-screening plant, you can reach our sales team 24/7 in the language you prefer. All you need to do is fill out and submit the form below. Our representative will contact you as soon as possible.

You can follow all our published articles on topics such as current developments in the sector, correct production techniques and quality raw material selection, and be informed about product comparison tables and other factors that increase profitability.

MAIN TYPES OF CRUSHERS INTRODUCTION In the world of industrial equipment, crushers are a crucial part of crushing and screening

Types of Rocks Used in Crushing Plants Different types of rocks used in crushing plants for various construction projects. Crushing

Types of Crushing and Screening Plants Introduction of Types of Crushing and Screening Plants: Crushing and screening plants are essential

We continue to make a mark in many countries around the world with the quality of our productions.

Through the experiences gained from the unique needs of each country, we remain bold and adaptable in the face of ever-changing global challenges. Looking towards the future, our main endeavor is to enhance productivity and profitability for our customers.