THE RELATION BETWEEN “CRUSHING AND SCREENING PLANT” AND “CONCRETE BATCHING PLANT”

Concrete stands out as the fundamental construction material in the construction industry. Its high durability and excellent workability play a critical role in the successful completion of projects. A concrete batching plant plays a central role in the production of this essential material. However, an ideal crushing and screening plant is also necessary for the production of high-quality concrete.

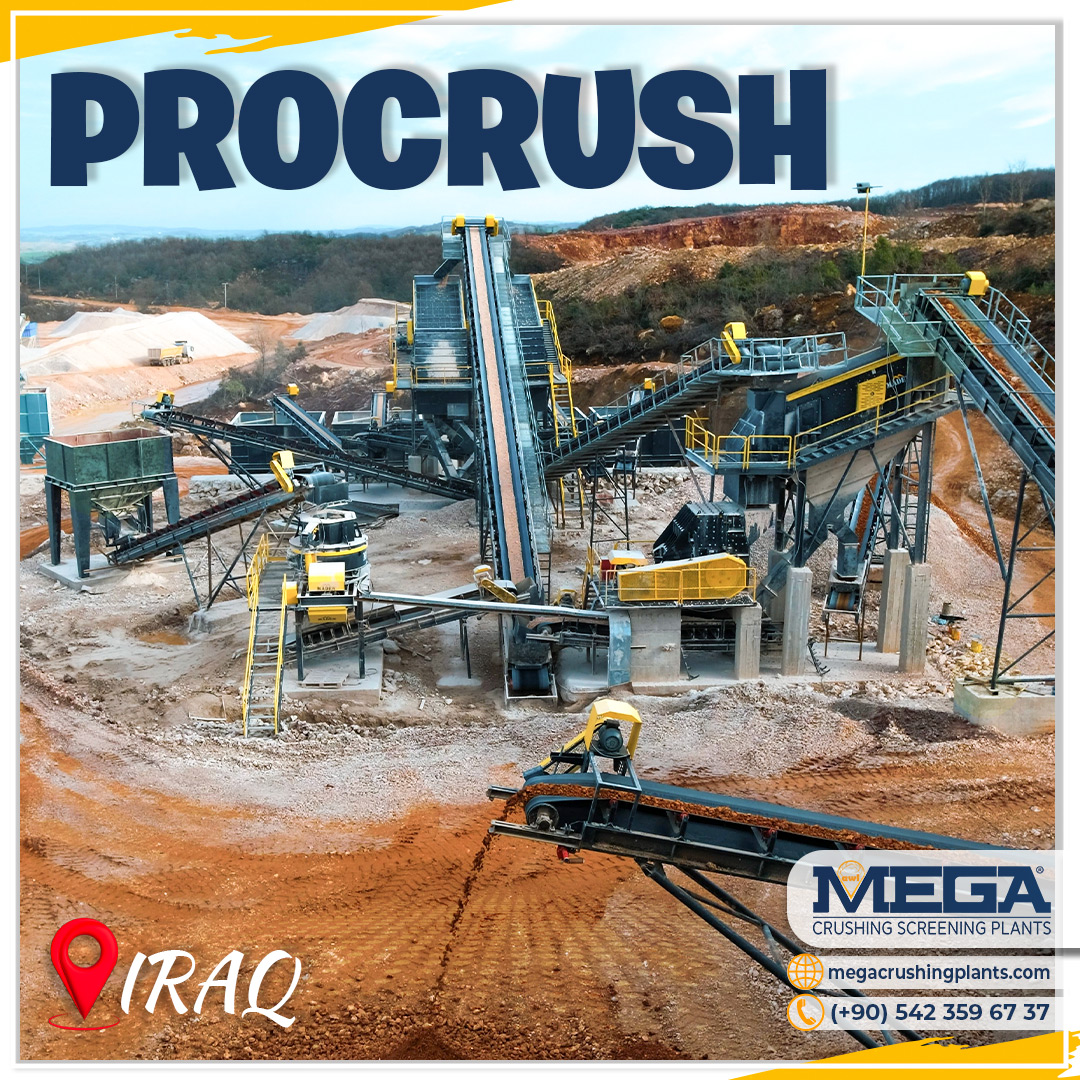

The crushing and screening plant processes natural stones and other raw materials to obtain various sizes of aggregates used in concrete production. In this article, we will explore the key relationship between the concrete batching plant and the ideal crushing and screening facility, and emphasize the significance of high-quality aggregates in concrete production.

An ideal crushing and screening plant should have the following features for the production of aggregates of appropriate quality for the concrete batching plant:

Efficiency and High Performance:

The ideal crushing and screening plant for a concrete batching plant should be furnished with modern equipment capable of operating with high efficiency. Precise crushing and screening processes ensure fast and efficient processing of raw materials. This saves time and costs, while at the same time increasing production capacity. High-performance equipment supports the increase in productivity and ensures continuous and uninterrupted production of the concrete batching plant.

Various Aggregate Sizes:

In order for concrete to have the desired strength, durability, and workability characteristics, it requires aggregates of different sizes. An ideal crushing and screening plant should be able to produce aggregates in different sizes.

Gravel obtained from crushing large-sized stones is further screened to obtain sand and dust in finer sizes. This variety is crucial to meet the requirements of different projects. Procuring aggregates suitable for different types and applications of concrete used in the construction sector enhances the performance of concrete and ensures the successful completion of projects.

As the author of the blog I’m planning to write an blog about most preffered aggregate sizes for concrete production.

Quality Control:

The quality of concrete is directly dependent on the quality of the produced aggregates. An ideal crushing and screening plant should prioritize quality control processes. Regular checks should be conducted to ensure whether the aggregates meet the standards, and adjustments should be made if necessary. Precise quality control methods and laboratory tests are employed to confirm that the aggregates adhere to the specified properties. This enables the production of high-quality concrete and ensures reliability in construction projects.

Minimizing Environmental Impacts

The crushing and screening process can cause environmental impacts such as dust, noise, and vibration. In an ideal facility, various measures should be taken to minimize these environmental effects.

Dust control systems prevent dust from being dispersed into the atmosphere, reducing negative effects on worker health. Sound insulation and vibration measures protect surrounding living areas and minimize environmental impacts. Additionally, proper management of environmentally sensitive waste is crucial.

An ideal crushing and screening plant should implement effective recycling and waste management measures. By using appropriate equipment and processes for recycling, used concrete pieces and other waste materials can be transformed into reusable materials. This supports environmental sustainability and contributes to the conservation of natural resources.

Safety:

Concrete batching plants and crushing and screening facilities must comply with safety standards. Worker health and safety should be a top priority, and necessary measures should be taken to minimize risks.

Personnel should be equipped with proper training and ensure full compliance with occupational health and safety regulations. Furthermore, regular equipment maintenance and adherence to operating procedures contribute to a safe working environment.

An ideal crushing and screening plant for a concrete batching plant offers a seamless combination of factors such as high efficiency, production of various aggregates, quality control, minimizing environmental impacts, and safety.

This comprehensive solution is indispensable for those seeking excellent results in construction projects. To guarantee the quality of your concrete and the success of your construction projects, the combination of vital components such as a concrete batching plant and a crushing and screening facility is inevitable. Being an integral part of your investment, it maximizes returns and positions you at the forefront of the industry.

“This powerful duo represents excellence and competitiveness in the construction sector.”

Contact us for our solutions to solve your problems…